Vacuum Tray Dryer

Vacuum Tray Dryer , vacuum tray dryer machine , Vacuum Tray Dryer Manufacturer

Vacuum Tray Dryer

cGMP Standard models range from 3 trays to 96 Vacuum Tray Dryer .Optionally Available Hot water system (Steam heated) with tank (Insulated), SS304 Steam Radiator/Electrical heaters, Circulation pump with FLP Motor and controls.

Vacuum Tray Dryer , vacuum tray dryer machine , Vacuum Tray Dryer Manufacturer by Shree Bhagwati.

Application : Vacuum Tray Dryer ,vacuum tray dryer machine , Vacuum Tray Dryer Manufacturer

Standard models range from 3 trays to 96 trays , Model 3 , 6, 12, 24 , 36 , 48 ,96 Vacuum tray dryer is wide used in intermediate pharmaceutical products , chemical, foodstuff and electronic industries. , Processing of packaged food , Sterilization of Spices, Raw materials , Petrochemicals , Chemical specialties , Chemicals , Recycling , Different types of sludge , Molding, friction and fiber compounds , Dyestuff , Plastics (fiber polymers) ,Vacuum tray dryer for Pharma, API Powders, Granulars, and Flakes Product Applications Powders, Non-Free Flowing , Ground Coffee , Fertilizer , Flour Mixes , Soup Base , Cake Mix , Powders, Free Flowing , Drink Mixes , Coffee Beans , Potato Flakes , Whole Spices , Granular Sugar , Grass Seed , Pool Chemicals etc and many more ………

Vacuum Tray dryer machine

For solvent in raw material can be recovered. If use SB series water ring vacuum pump or hydraulic inject vacuum pump sets, condenser cannot be used and the investment could be saved, Suitable for drying heat sensitive raw materials that can decompose and polymerize and metamorphose at high temperature.

We Manufacturing of GMP / cGMP Vacuum Tray Dryer machine & equipments , Condenser (Shell & tube) and Receiver in SS 304 with Isolation valve and Flow Glass in between to monitor condensation attachment for is the most commonly used batch dryers for different kind of products for moisture removing. The Cabinet box type shaped machine has a doors (two door in case of larger models) for loadings and unloading tray materials.

The drying process require a few hours to time depending upon the product and its surface loads. Automatically controlled vacuums and temperatures profile can be set to prevent going over the threshold of the critical products temperature. Dimension of the vacuum system play a crucial roles in the designs of drying cabinet. Trays (without back folding) in SS316 rounded corners and edges, If intense foaming of the product is desired, the transfer to operational vacuum level must take place very quickly so that the vapours produced are taken out directly or through the means of a steam jet compressor and the non-condensable vapours are extracted by the vacuum system.

stainless steel vacuum tray dryer

Safety Features : Vacuum Tray Dryer ,vacuum tray dryer machine , Vacuum Tray Dryer Manufacturer

Temperature controls, Process controls, Vacuum relief valve, Over load protection and Emergency stop.

OPTIONAL OF

- Condenser and receiver are made in SS 316

- 50 mm thick glass wool insulation on the vacuum chamber outer surface except door

- Hot water system (Steam heated) with MS tank (insulated), SS304 steam Radiator/Electrical heaters, Circulation pump with FLP Motor and controls.

- Option for advance PLC Controls with HMI touch screen..

- Option for Flame Proof Electrical.

- Option for lump breaker.

- Option for condenser, Receiver & Cyclone for solvent recovery.

- Option for heating media steam/ hot water / hot oil.

Condenser (Shell & tube) and Receiver

Key Features:

- Total cGMP finish construction.

- All contact part are made out of Stainless Steel 304 / SS316 / SS316L Material in cGMP models.

- Hollow pad type heating shelves which are easily removable for maintenance.”

- Condenser and condensate receiver fixed on the dryer body or stand alone for remote installation.

- Full welded skirt on vacuum dryer body for flush mounting through the wall.

- Validation ports and nitrogen purge nozzles.

- Heavy Duty Design to with stand Full Vacuum.

- Can be designed to customers specification requirements.

- Digital Temperature Indicator (FLP) at H. W. Inlet & Outlet.

- Glass View Provided on door And Receiver.

Vacuum Tray Dryer range 3 , 6, 12, 24 , 36 , 48 ,96 Vacuum tray dryer with Condenser and receiver for drying process depending upon the products, Vacuum Tray Dryer

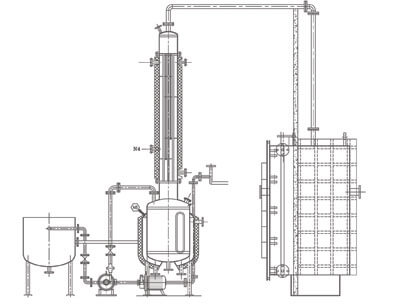

Vacuum Tray Dryer machine layout

Vacuum Tray Dryer